CONSTRUCTION, MAINTENANCE & RENEWAL MACHINES

A transformative approach to Global Rail Construction, Maintenance and Renewal projects

Rail networks around the globe are facing challenges delivering world-class services whilst managing the challenges of aging infrastructure. Contractors and Infrastructure Operators are required to deliver construction, maintenance, and renewal projects in a more efficient, safer, and cost-effective way. This poses several challenges due to the high upfront and operational costs of equipment, the high resource demands, the technological dependency and low adaptability of the machinery, and the logistical complexity of each project.

Unipart Rail and Thomson Engineering Design Ltd have recognised these challenges and are working in partnership to deliver a universal solution for global rail operators and contractors, providing a system which offers all of the benefits of high output train-based systems, at a fraction of the cost and with no restriction on the type of lines they can be used on.

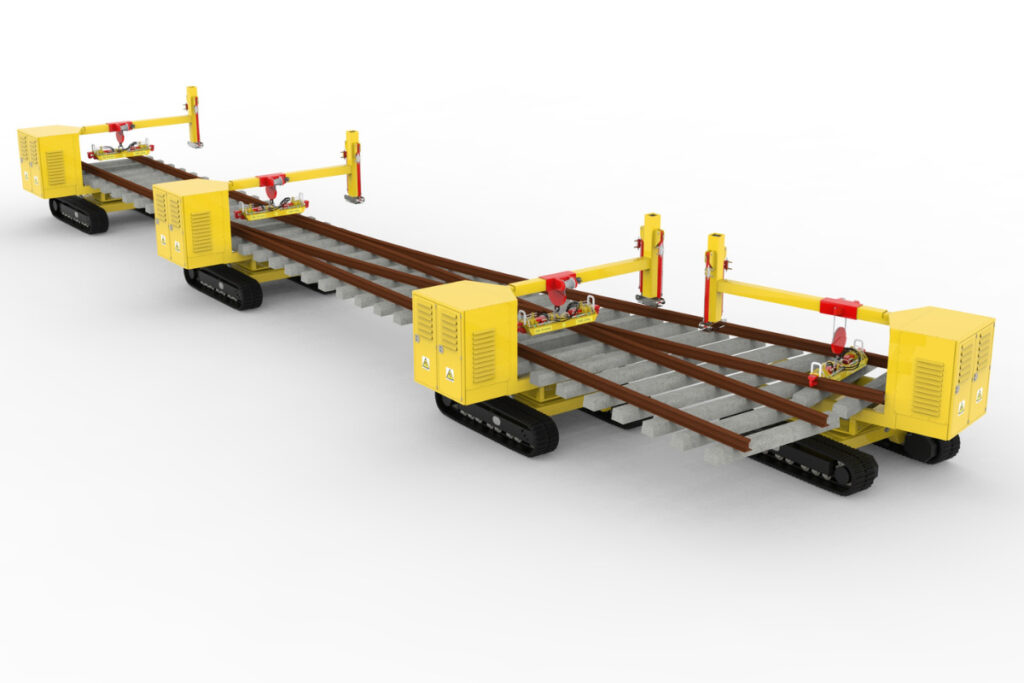

SLEEPER LAYER

The Sleeper Layer delivers a new approach to the laying and positioning of sleepers in track construction and renewal projects.

Self-propelled and semi-autonomous in operation, this unique machine offers high output and high precision, requiring only 1 operator and precisely delivering up to 1000 sleepers per hour, onto the track bed.

The sleeper spacing is controlled by a shaft encoder on a wheel running on the track centre line, which can be adjusted to any desired setting via a touch-screen control panel.

The machine is powered by a 55kW JCB diesel engine built to the latest emissions specifications. The plc control maximises efficiency by monitoring the engine parameters and hydraulic system performance, minimising fuel use.

Features & Benefits

- High output and precision

- Semi-autonomous operation

- Adaptable to projects & locations

- Rapid deployment & delivery

- Low capital and operational costs

- Remote machine diagnosis

- Reduced manpower

- Increased operator safety

- Decreased operator fatigue

- Comprehensive training package

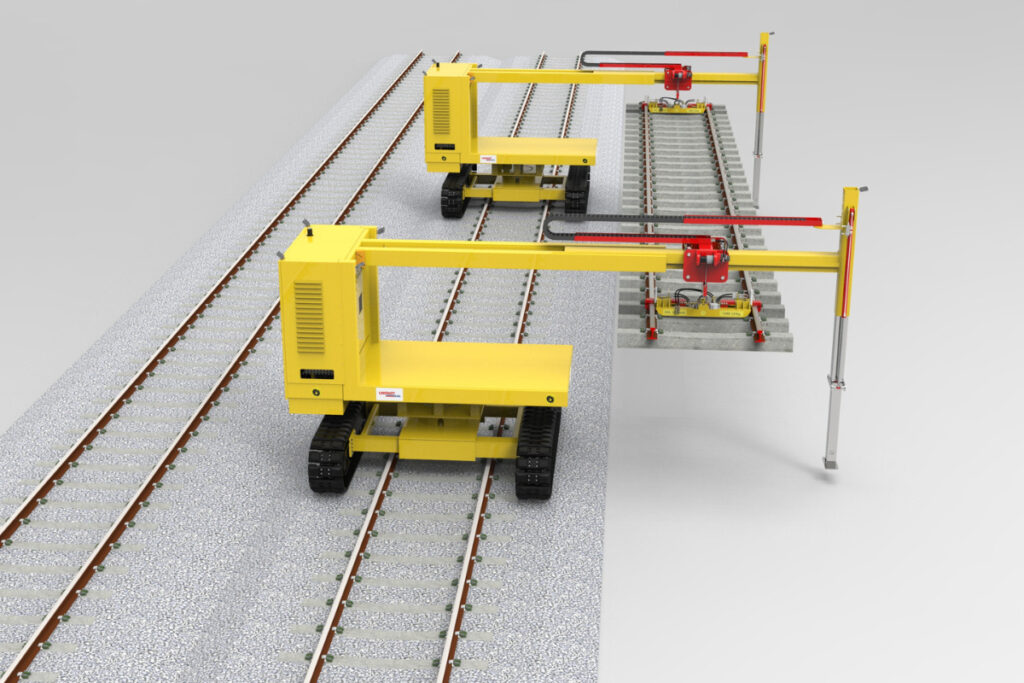

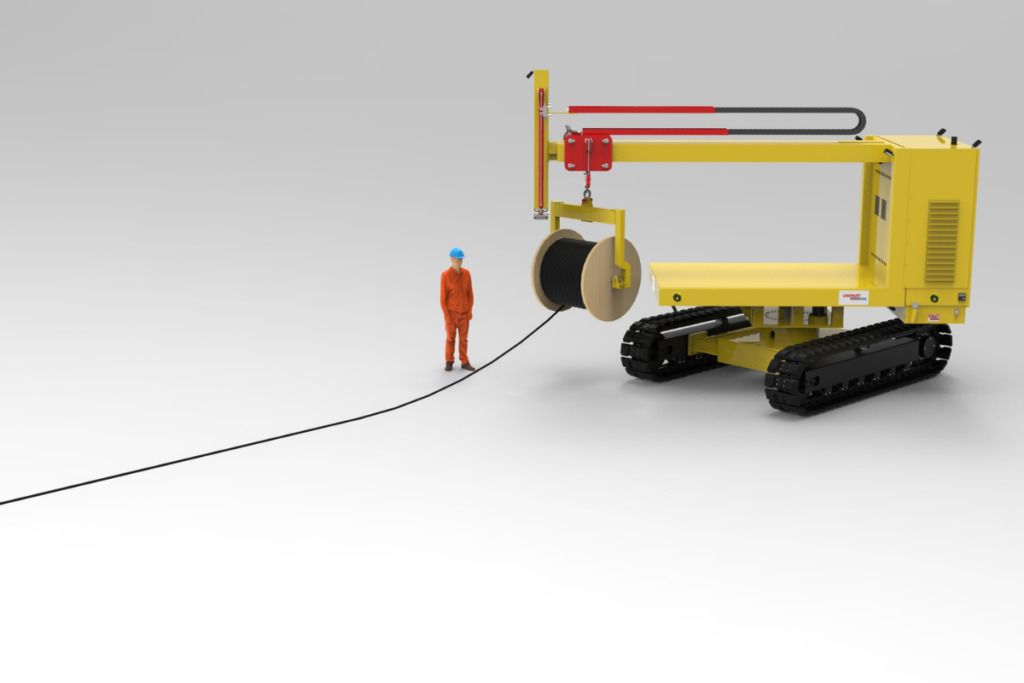

RAIL HANDLER

Our Rail Handler is an innovative approach to the moving, transposing, and positioning of rail.

This powerful and versatile machine offers a variety of applications and benefits for rail maintenance teams, including lifting and transporting rails, and threading long welded rails.

The machine offers the capability to install, remove, transpose or replace rails quickly and safely, even under live overhead catenary power lines.

The Rail Handler can also be used for a variety of other applications including repadding, clearing ballast, and providing power for Hydraulic tools. As the Machine uses attachments, it can also be tailored to meet other project requirements increasing the utilisation and adaptability of the machine.

Features & Benefits

- Efficient rail handling in any line open working

- Can transpose up to 2 miles of rail per hour

- Ability to handle 1 or 2 rails simultaneously

- Increased operator safety

- Works under live overhead lines

- No risk of damage to rail fastening system nor the sleeper shoulder

- Rapid deployment and transportation

- Multiple applications and accessories

RAIL CLIPPER

Our Self-Propelled Rail Clipper provides clipping and de-clipping of rail fastening solutions in a safe, efficient, and fast manner.

The powerful rubber tracks make this machine capable of loading and unloading itself onto delivery vehicles and to move on and off the rails, without need for a crane. Once on the rails, the machine can lift sleepers in track renewals work, as well as either setting or releasing the clips, all at high speed as a result of the semi-autonomous mode.

The machine design incorporates interchangeable modules for the most popular clip types for Pandrol FC and FE Fastclips. Options for Pandrol PR and E-clips and Vossloh fasteners can also be requested, making it suitable for the majority of the global rail network.

Features & Benefits

- Self loading and unloading

- Self on and off-tracking

- Radio remote control increases safety

- Interchangeable Clipping/De-Clipping modules for different fastening systems

- Semi-autonomous operation

- Minimal training requirements and simple set up

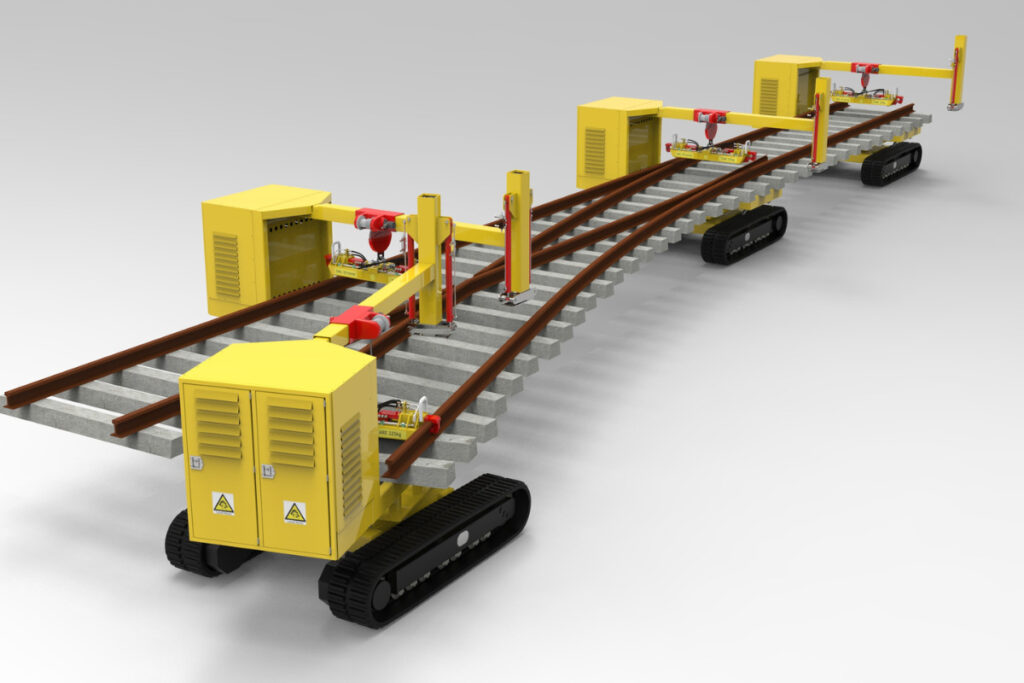

Unipart Rail, in partnership with Thomson Engineering Design Ltd, is delighted to have won the Innovation in Railway Construction competition, funded by the Department for Business and Trade and being led by Innovate UK, in partnership with the Global Centre of Rail Excellence (GCRE).

The funding received through this competition will enable Unipart Rail and Thomson Engineering Design Ltd to propel their groundbreaking initiatives in revolutionising the railway construction sector, through the development of a travnsformative solution for global rail panel handling.

MoRPH (Mobile Rail Panel Handler), is a new machine designed to disrupt the current track renewal and maintenance supply chain by providing all of the functionality of specialist plant hire equipment, at a much lower cost and increasing the availability of handling machinery, allowing major renewals work to be delivered on much shorter timescales.

The project will be developed at the new GCRE facility in South Wales.