Unipart Rail brings new technology to the industry

We develop our own, source from innovators, and collaborate with SMEs to deliver the best innovation possible to deliver increased better performance, operational efficiencies and maintenance savings.

Why our innovation matters

Our customers demand constant evolution of technology. We want to ensure that we remain the supplier of choice for our rail customers. Delivering new, reliable, performance-improving and cost-effective products and services is the driver of Unipart Rail's sustainable business model.

How we bridge the divide between our customers and innovators

In house, through great sourcing, and by investing in collaborative development, we nurture innovation through the approval process and into daily use.

Realising your innovation though our world-class manufacturing solutions

High quality factory production delivers great innovation to the market. Our manufacturing services are built on decades of capability, and continual adaptation to new methods and technologies.

We work with the best to get the best

Collaborating with leading rail academics across Rolling Stock and Infrastructure, we embrace the key themes of the Rail Technical Strategy 2020, supplementing our Digital capabilities in partnership with UKRRIN and the Sheffield City Region Local Enterprise Partnership (SCR LEP).

Digital as a core component of innovation

The railway is hungry for transformative performance improving digital technology, however this requires subtle integration, informed by a comprehensive understanding of how complex rail network systems operate.

Driving Performance Improvement with New Innovation

Innovation must deliver performance improvements for the travelling public and freight operators. whether it is our own innovations or those developed by SME partners, we always make sure that they are aligned with better asset management and performance, lower cost or operational improvement.

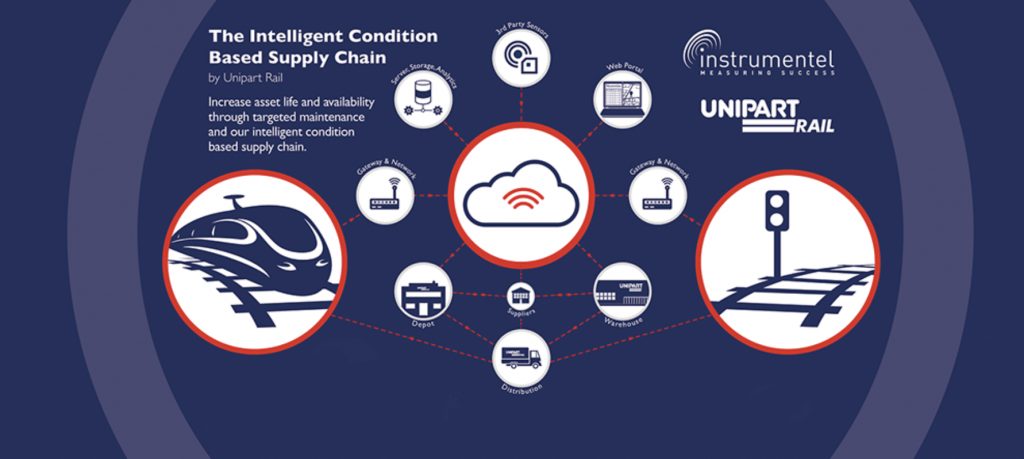

The Condition Based Supply Chain aims to monitor thousands of assets and translate the data colelcted into actionable information – either supporting imprioved decision making or automating the supply chain to target maintenance before failure.

Why we Innovate

Our customers demand constant evolution of technology. We want to ensure that we remain the supplier of choice for our rail customers. Delivering new, reliable, performance-improving and cost-effective products and services is the driver of Unipart Rail’s sustainable business model. As rail networks develop and new technologies are introduced, old ways of doing things need to be modernised. Whether it’s developing digital alternatives, re-imagining whole systems or creating someting that’s totally new, we know that there is always a better way to do things and manage your assets better.

How we Innovate

In house, through great sourcing, and by investing in collaborative development, we bring innovation through the approval process and into daily use.

We promote an open innovation model to ensure we listen carefully to our client requirements and actively encourage collaboration with industry partners including academics, SMEs and Technology Start-Ups to ensure our solutions are optimised for UK and global rail markets.

Our technical and engineering teams are focussed on delivering support to our customers – from developing alternatives right through to their introduction and on-going support.

Manufacturing Capability

High quality factory production delivers great innovation to the market. Our manufacturing services are built on decades of capability, and continual adaptation to new methods and technologies.

Though our own extensive workshop facilities, and those of our partners MetLase, Instrumentel, Park Signalling, Unipart Dorman, Comms Design and Westcode, we offer electrical, electronic, electro-mechanical and mechanical hardware manufacturing, plus in-house software development teams, that can take a solution from initial requirement to volume production and aftermarket support.

So if you need to scale-up production of your innovation and take it to market, speak to us.

Our Rail Innovation Partners

Our Doncaster Head Office is the proud home of the UKRRIN technology hub (United Kingdom Rail Research Innovation Network). In collaboration with leading rail academics across Rolling Stock and Infrastructure, we embrace the key themes of the Rail Technical Strategy 2020, supplementing our Digital capabilities in partnership with the Sheffield City Region Local Enterprise Partnership (SCR LEP).

Our commercialisation skills are rooted in a long history of working and innovating in the rail sector. We work with SMEs to help them realise the full performance-improving potential of their innovations by steering them through the standards and approvals process, trialling and launching new products across the world. Our world-wide operations and local expertise in many markets means that you have a ready-made route to market for your innovation.

The DIGI-RAIL project provides technical and business/commercial support to eligible SMEs in the Sheffield City Region looking to enter or grow their business in the rail industry, focussing on supplying the Digital Railway.

The UK Rail Research and Innovation Network (UKRRIN) is designed to create powerful collaboration between academia and industry, aiming to provide a step-change in innovation in the sector.

Digital Capability

The railway is hungry for digital technology, however this requires subtle integration, informed by a comprehensive understanding of how complex rail network systems operate.

Digital twinning, testing and migration from current to future state is key to success. Risks must be assessed and mitigated to ensure that the failsafe approach that underpins our critical systems are maintained. Unipart Rail’s engineering and technical expertise drives our digital capabilities to successful deployment of new solutions that add real value.

Our Digital Team harnesses hardware and software skills to deliver successes, and to challenge convention in a positive way.

Group Technology Capability

Unipart Rail works with our Group technology experts and leverages industry leading manufacturing capabilities to ensure our products and services are fit for the demands of the World’s Railways.

Our supply chain and logistics offering is unrivalled in the rail industry and our extensive client base ensures innovative products are adopted on an unprecedented scale, helping to drive the rail industry towards 4.0.

We also provide commercialisation and manufacturing services for SMEs with new innovations.